How is UV LED technology connected to the printing industry?

Being asked about printing technology, most of all people will refer to home printers or copy/orienting shops. But these printer types are only a fraction of what actual printing technologies are and which applications are covered. From newspapers, to wallpaper, to packaging to bottle labels, all of these are printed materials and require specific printing processes.

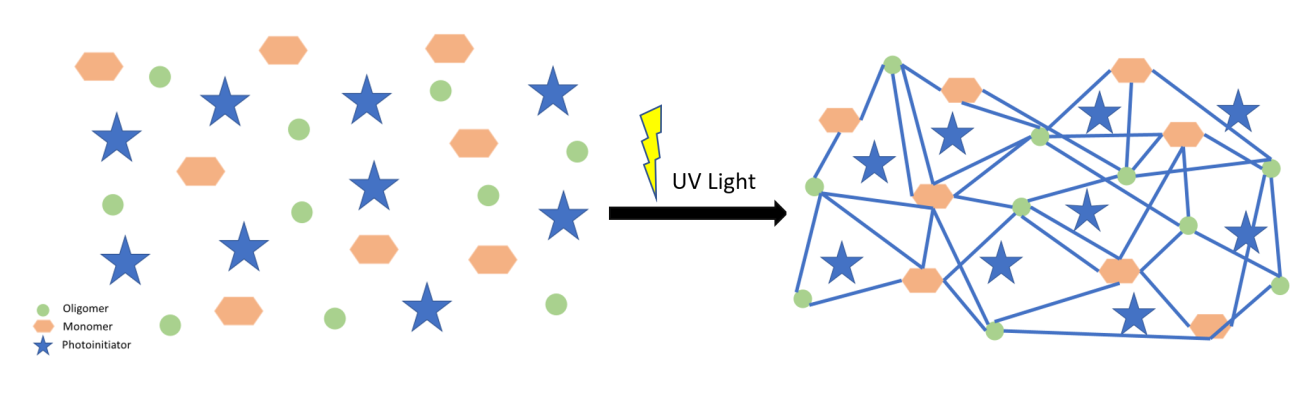

Ink curing as described in picture 1 offers certain advantages compared to other methods used by some other such as hot-air drying. LED curing technology significantly reduces the surface temperature. Less heat means less energy wasted, which also means less costs for the application itself. On top the low power consumption of LEDs is one of the main advantages as they offer up to 70% of electricity-cost saving compared to hot air drying. A further benefit of implementing LED into printing technology is that LED offers fast on/off option allowing them to only be used when required, which again helps saving on energy costs.

The UV LED market in the printing industry is a fast growing one as there are more advantages such as its versatility and adaptability to various printing machines. Heraeus Noblelight offers water and air cooled systems in various power ranges even including systems for easy maintenance (Plug-and-play) – click here to learn more.

References:

Kipphan, Helmut. (2001). Handbook of print media: technologies and production methods. Berlin: Springer